In 2024, one of the most frequent questions I received was whether B’s processor was compatible with the 3xxx series Jobo tanks. My answer was always yes, as it fit and rotated well, but these large diameter tanks needed some monitoring. So, I went on to make B’s Processor even more compatible with these giants.

First, I needed to test it myself, so I found a “cheaper” 3010 tank on eBay. This also allowed me to do some 4x5 testing and comparison with my Mk3 reel. I am happy to say that the upcoming Mk3 will perform as well or better in rotation.

Side Note: If you use a 3010 tank, the best results come from using the processor on mode 3 with the normal 12v power supply. Some users switched to a 15v power supply to get closer to the Jobo recommended rpm, but during this testing round and to my sruprise, the normal power supply provided the best evenness.

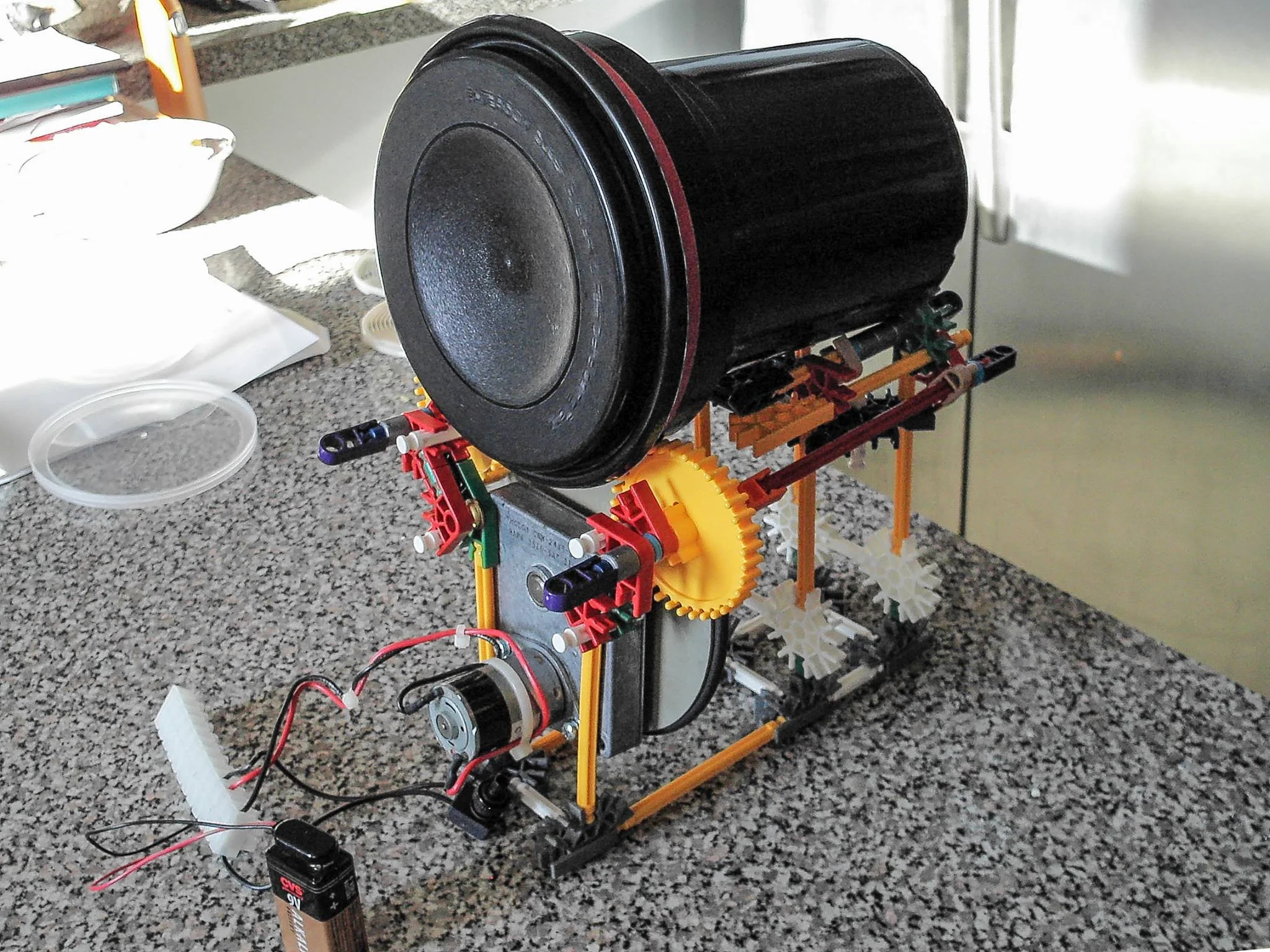

Jobo 3010 expert drum on B’s processor with premium trigger and extension

Next, I made the processor as physically stable as possible, leading to the creation of the Processor extension. If you plan to use larger tanks like the Jobo 2500/3000 series or the longer Paterson 8, the extension is essential, and you will have to care less for balance.

While working on this, some users reported synchronization issues with the 3xxx series on B’s processor. For one user, flashing new modified firmware I provided with different synchronization timing solved the problem, but this would create the same issue with smaller tanks. Flashing new firmware is also not easy for the average user. I am still working on a simple solution and will release new firmware soon. (A simple one would be to use small apps like Avrdude or Xloader but these are not compatible with the board I use… If you have skills in that domain, please contact me)

After further investigation, the issue was caused by the larger tank diameter and also inconsistent rpm motors in B’s processor. The motors we get vary from 165 to 185 rpm, for a nomilal 170rpmand the faster ones can cause timing issues. If you encounter synchronization problems, try synchronizing in a different mode and then switch back to the desired mode. I prefer to synchronize in mode 3 for quick chemical distribution and then switch to mode 1 for the rest of the development.

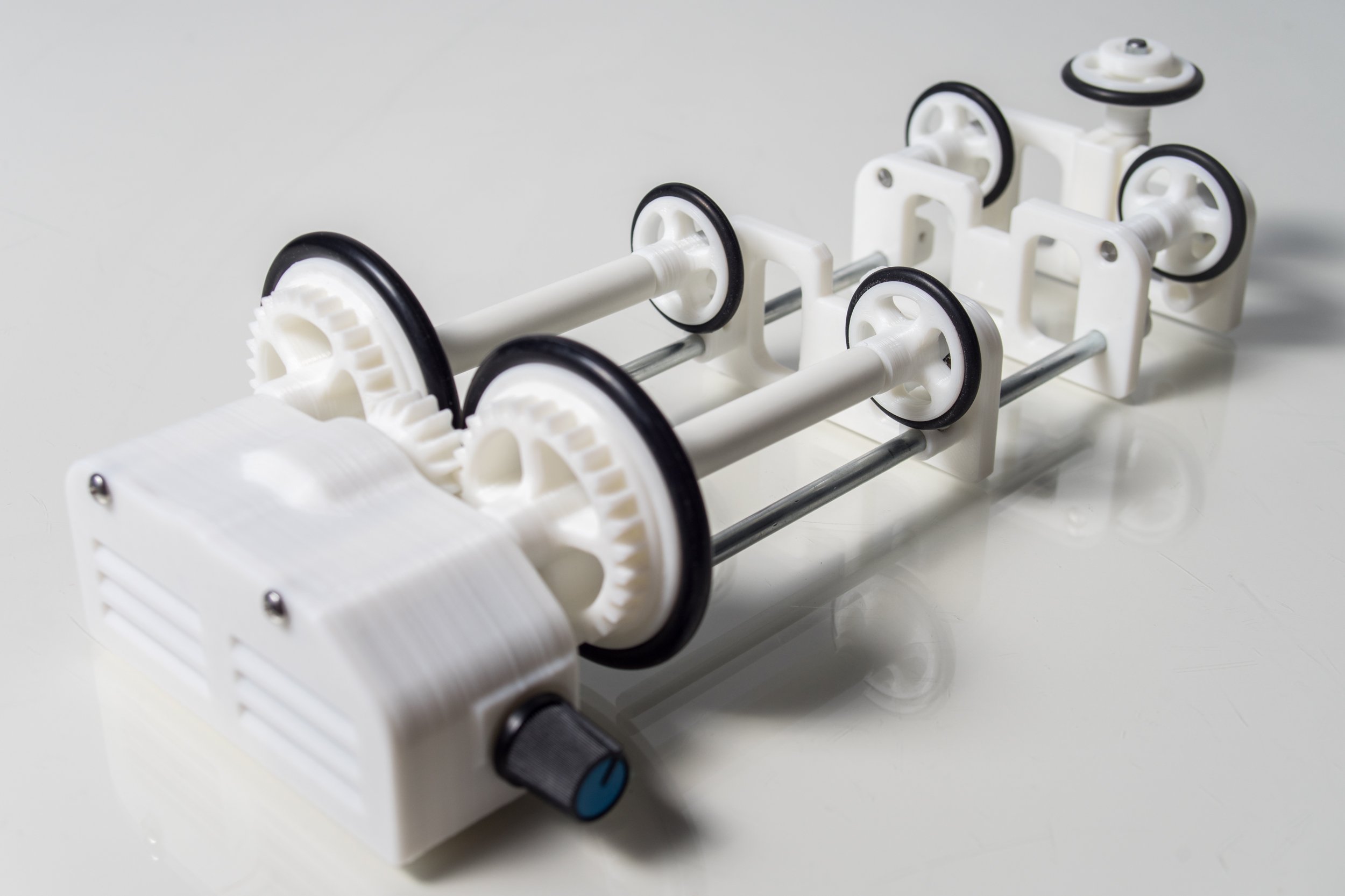

To manage timing consistently, I created a different trigger for large tanks and adapted magnet spacing. This led to the development of the Premium magnetic trigger, which simplifies installation and ensures perfect magnet-to-track spacing since I integrated the track into it, making the 3xxx tank more stable. Although the new firmware will be compatible with any spacing or tank size, I liked the functionality of this premium trigger so much that I made one for each tank size, from steel tanks to the 3xxx series.

B’s processor will continue to be delivered with its universal flexible trigger,

You can now find all sizes all sizes in the store now, happy developing! Stay tuned for more new things 😊

Benoît.